PRECISION DEGREASING FOR SENSITIVE MATERIALS

NON-FLAMMABLE

NON-EXPLOSIVE

ODOURLESS

VERY LOW SURFACE TENSION

DESCRIPTION

Technical solvent compatible with all substrates. Developed for its neutrality in terms of sensitive materials, such as polymers, plastics, elastomers, rubber, composites including carbon-carbon, TPU, and all coatings including conformal coatings for electronics.

Non-flammable, non-explosive, with no self-ignition point, it can be used on components at high temperatures.

Degreasing, washing, decontamination, particle removal.

APPLICATIONS

Vapour phase degreasing and cleaning of oils, greases and polishing pastes

Removal of perfluorinated greases

Vector for depositing perfluoropolyether oils

Cleaning of laboratory equipment and precision components

Cleaning of organic or inorganic optics

Cleaning of electronic components

Cleaning of medical components

Cleaning of hard disk drivers

Cleaning and washing of plastics

PROPERTIES

|

PROPERTIES |

STANDARD or METHOD |

VALUE |

UNITS |

|

Appearance |

Visual |

Clear |

- |

|

Colour |

Visual |

Colourless |

- |

|

Density at 25°C

|

NF EN IS0 2811-1: 2016 |

1.720 |

Kg/m³ |

|

Flash point |

ISO 2719: 2016 |

without |

°C |

|

Evaporation rate at 23°C |

- |

15 |

seconds |

|

Surface tension at 25°C |

NF ISO 6295 |

12 |

(Dynes/cm2) |

|

Boiling point |

ASTM D 5399 |

55 |

°C |

|

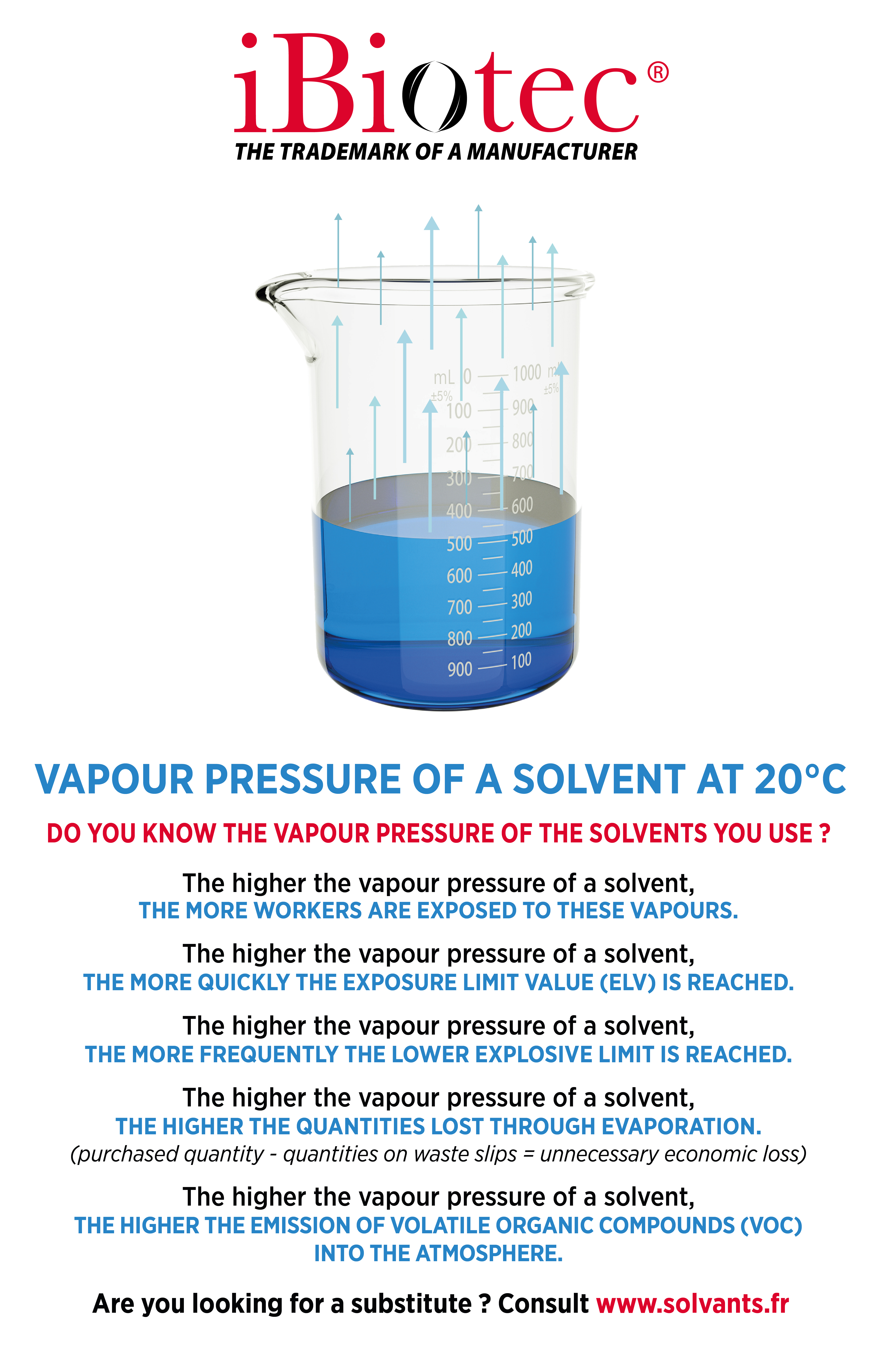

Vapour pressure at 25°C |

NF EN 13016 |

270 |

(kPa) |

|

Freezing point |

ASTM D 97 |

-90 |

°C |

|

Vapour phase machine set point |

- |

50 |

°C |

|

Breakdown voltage |

IEC 156 |

>25,000 |

v |

|

ODP (Ozone Depleting Potential) |

|

0 |

|

PRESENTATION

30 kg drum

COMPATIBILITY WITH PLASTIC MATERIALS AND ELASTOMERS

The test protocol chosen was voluntarily made severe in order to meet the technical requirements of the users without reservation. The evaporation speed of BIOSANE T 216 is less than 1 minute. The contact time for some industrial applications, particularly in baths, may be longer. The results were therefore measured after an immersion voluntarily extended to 1 hour.

For each specimen of the material to be tested, the dimension and weight are measured. The specimens are immersed for 1 hour in the solvent medium to be tested at room temperature (22°C). The tests are reproduced 3 times. After immersion, the weight variation, dimensional variation and visual appearance are established; the average of the 3 measurements is taken into account.

DIMENSIONAL VARIATION PERCENTAGES

|

PLASTICS |

T 216 |

|

Acrylonitrile-butadiene-styrene (ABS) |

0.000% |

|

Polyamide 12 (PA 12) |

0.000% |

|

High Density Polyethylene (HDPE 500) |

0.000% |

|

Polymethyl methacrylate (PMMA) |

0.000% |

|

Polypropylene (PP) |

0.000% |

|

Polyvinylchloride (PVC) |

0.000% |

|

ELASTOMERS |

|

|

Buna SH 65 |

0.578 % |

|

Buna SH 72 |

0.565% |

|

Butyl |

-0.295% |

|

Chlorobutyl |

0.000% |

|

Chlorobutadiene (Neoprene®) |

0.000% |

WEIGHT VARIATION PERCENTAGES

|

PLASTICS |

T 216 |

|

Acrylonitrile-butadiene-styrene (ABS) |

0.002% |

|

Polyamide 12 (PA 12) |

0.001% |

|

High Density Polyethylene (HDPE 500) |

0.001% |

|

Polymethyl methacrylate (PMMA) |

0.024% |

|

Polypropylene (PP) |

0.003% |

|

Polyvinylchloride (PVC) |

0.003% |

|

ELASTOMERS |

|

|

Buna SH 65 |

0.813% |

|

Buna SH 72 |

1.294% |

|

Butyl |

-0.442% |

|

Chlorobutyl |

-0.051% |

|

Polymerized chlorobutadiene (Neoprene®) |

-0.406% |

The tests carried out demonstrate the perfect compatibility of BIOSANE T 216 with the plastics and elastomers tested.

AREAS OF USE

Cleaning, washing, decontaminating and drying electronic components, eliminating leakage currents that cause circuit failures...

Used for optimum cleaning of single or multiple input/output tracks, passive and active, analogue or digital components.

Precision cleaning of ocular optics, mirrors and lenses used in aeronautics or space flights.

Decontamination of laboratory equipment, scanning electron microscopes, Auger spectroscopes.

Cleaning of High-Tech composite parts.

Removal of perfluorinated greases.

Cleaning of medical components.

Cleaning of hard disk drivers.

Cleaning of thermoset or thermoplastic plastic materials.

With no change to the PMMA crystal’s refractive index even after prolonged contact.

Looking for another product?

|

Discover our entire range by clicking on the photo |

Manufacturing, lubrification, cleansing, protection,

IBiotec® Tec Industries® Service

offers a wide range of products reserved for industrial area

If you wish for :

a free sample

a technical advice

a product data sheet

a safety data sheet

IBiotec® Tec Industries®Service

manufacturer of technical chemical products.

Welcome to our website.

.jpg)